-

Answers

-

How do I keep my whitewalls

clean? For simple clean-up, use soap and water.

We have brought to market our own whitewall tire

cleaner that can be found by clicking this link. For

over-the-counter type products, you may use Mr. Clean Magic

Eraser or Simple Green Extreme. Avoid products that contain

strong cleaning agents such as bleach or lye. Products like

Comet Cleanser, Ajax, Brillo or Bar Cleaner have bleach in them

and these chemicals will cause yellowing and cracking of the

whitewalls. Do not use Armor All on whitewalls. Sadly, some

products that are designed specifically for cleaning whitewalls

have bleach in them, so, be careful.

-

What is the difference between

bias-ply tires and radial tires?

-

Bias-ply tires are: 1) Most authentic,

period-correct look for a vintage car. 2) Less expense

generally. 3) In most cases, wider whitewalls and more choices

of brands and whitewall sizes and appearances. 4) The most

notable appearance features are the straight up and down or

vertical side walls, the attractive "pie-crust" edges of the

tires that resemble scallops and the period-correct looking

tread patterns. A good example of a bias-ply tire with a wide

four inch tire can be seen on this link:

BIAS PLY TIRE.

The disadvantages of

bias-ply tires are that they do not ride as nice as steel belted

radials will or perform as well on cornering or in wet

conditions. They tend to follow cracks or seams in the pavement

("tram-lining")

and they will "flat-spot" if they sit too long without use,

although the tires will smooth out after driving for a given

distance. If you are running bias-ply tires presently that are

over 6-8 years of age, they are probably in need of replacement

and new bias-plys will probably perform much better than

outdated rubber will. Bias-ply tires probably will not have as

long of an estimated tread life and may not have a high enough

speed rating if you have a need for speed.

-

Steel-belted radial tires have: 1) Superior

ride and performance. 2) Attractive design. 3) Period-correct

appearance and whitewall stripes for more modern cars. 4) Longer

tread-life and 5) Speed rated for higher speed driving. The

disadvantages are: 1) Higher cost. 2) Can

cause cracking or harm to antiquated wheels. 3) May detract from

a vintage presentation on an older car. 4) In tight quarters, a

steel belted radial may be wider than needed and could rub or

make contact with a fender skirt or body panel. Please click

here to see a fine example of steel belted radials on a

collector car:

STEEL BELTED RADIALS.

-

What precautions

should I take when I receive my tires from you?

When your new tires arrive, confirm that you

have received the correct size tire you ordered or

your car requires before having them mounted. Your

new tires should come wrapped in wide plastic

strips. Most brands have the whitewalls covered with

a thin blue coating to protect the whitewall. This

can easily be scrubbed off with soap and water and a

scrub brush. Inspect your whitewalls for any

blemishes or flaws. Report any problems to us if you

should discover them. Under no circumstances should

you stack the tires one on top of each other. If

this occurs, even for a brief period of time, the

black finish on the tire will stain the whitewall,

in some cases, permanently. This is called a "carbon

transfer". This is not covered by warranty and is

totally due to improper handling of the tires. Be

careful that your installer does not stack the tires

on top of each other out of your presence and then

try to tell you the tires came this way! Take note

of the recommended tire inflation pressure and

follow it. If you run inner-tubes, it is critical

that you inspect the inside of the tires for any

inspection tags, "mold marks", sharp edges or

foreign objects. These things can puncture your

inner-tubes.

-

What should I be aware

of when my whitewalls are mounted on my wheels?

We recommend finding an installer that is

familiar with whitewall tires and has some measure

of experience. It is not unusual for whitewall tires

to call for weights that amount to 1% of the

combined weight of the wheel and tire. For example,

a wheel and tire weighing 60 pounds may take six

ounces of wheel weights. Some

technicians will tell you this is way too much

weight but they fail to realize that the whitewall

is on one side of the tire only and is a thick,

heavy piece of rubber that simply requires more

weight to balance in some cases. If high amounts of

weight are necessary, a thorough installer will

dismount and rotate your tire 180 degrees and

re-balance. Matching the high and low spots of the

wheel and tire can also result in less weight being

necessary. Clip-on type weights are not recommended.

Clip-on type weights can also damage your

inner-tubes if you run them and can harm the finish

on your chrome or painted/powder-coated wheels

creating a gateway for rust. Also, these type of weights often will fall off with

whitewall tires. Stick-on weights are preferable. A

precision balance can best be achieved by using a

"finger-attachment" and balancing by the stud holes

which is called, "lug-centric". Using a cone in the

center hole of the wheel is called "hub centric" and

generally will result in a less precision balance

with whitewall tires. Take careful note if your

installer harms or stains your new whitewalls.

Our wheels and tires MUST BE balanced using a STATIC

setting, never dynamic. Do not allow your installer to inflate

your tires beyond 40 pounds of pressure to seat the

beads.

-

What size tire should I

select for my car? If you are still using

your original wheels or have wheels in the original

sizes, we can research the size for you and make

recommendations. If your car came with bias-ply

tires and now you wish to change over to modern

steel belted radial tires, you may find our Tire

Cross Reference Size Chart useful.

Please click here to view it.

If your car no

longer has the original size wheels on it, you

should be careful to select an appropriate size tire

for your wheel and also a tire that will fit in your

wheel wells without rubbing on the body, frame or

anything else. Please allow us to help you select

the correct size for your car.

-

How wide of a wheel will my

tire fit?

Each tire has a specific

rim width range on which the tire can be mounted.

Failure to follow rim width recommendations may

result in poor tire performance or possible wheel

and/or tire failure. Choosing a wheel near

the middle of the range will give a balance between

ride quality and handling. A wider wheel will

improve handling at the expense of ride quality,

while a narrower wheel will improve ride quality at

the expense of handling. Consider these compromises

when selecting wheels.

Please click here to view a list of approved rim

widths. If you use Bias-Ply Tires, simply

refer to our Tire Cross Reference Chart to convert

your bias-ply size to a radial size. Most of the

tires we sell display a recommended rim width or you

can simply email or call us.

-

Can I mix steel belted

radial and bias-ply tires? It is recommended

that all tires be of the same size, construction,

(radial or non-radial) and speed rating. If tires of

different speed ratings are mounted on a vehicle,

the tires with the lower speed rating will limit

permissible tire-related vehicle speed and handling.

The construction and handling characteristics of the

two differing tires can lead to performance and

safety issues. It is our belief that they should not

be mixed.

-

What is the

difference between the various brands of tires you

sell? There are obvious price differences

between the brands. Notwithstanding price, in the

same tire size for example, the whitewall sizes may

be different. Some are wider and some are smaller.

The tread patterns may also look quite different as

well. Some tread patterns may look like they are

more from the '70's as an example while others may

look even older. There are also differences in

estimated tread life and in the warranties that are

offered. Even though the tires may have the same

size description, you may note that diameters and

widths can differ between brands. We would be happy

to point out all these differences and help you

select the most appropriate tire for your

application.

-

Can I run

passenger car tires on trucks and trailers?

It is not a good idea. There are

significant differences between passenger car tires

and “Special Trailer” (ST) tires. A passenger car

tire is not designed to carry heavy loads for

extended periods of time while an ST tire is built

for such purposes as well as low rolling resistance,

long-life and stability while towing. It should be

noted that an LT or light truck type tire will work

as an alternative to an ST tire. An ST tire is

engineered to carry ten percent more load than a

similar sized passenger car tire. As a result, the

tire may have different steel belts, plies, beads,

thickness and diameter as compared to a passenger

car tire. The treads are also created to minimize

the tires squirming around. The tires also contain

different materials that allow the tires to stand-up

better to the elements while in storage. One big

concern when running a passenger car on a trailer is

that the side walls are not as strong as an ST tire

and can aggravate trailer swaying. The flexible side

walls of a passenger tire could cause the trailer to

sway badly enough that the driver could lose

control. We wouldn’t want to risk injury to life or

limb or to your special vintage trailer by using the

wrong type of tire.

-

Do you recommend I

have my car aligned after I mount my new tires?

Yes we do. In most cases, our customers indicate

that they have not had an alignment in some time to

begin with. An accurate wheel alignment is critical

to balance the tread-wear and performance a

vehicle's tires deliver. Regular wheel alignments

will usually save you as much in tire wear as they

cost, and should be considered routine, preventative

maintenance. Since there are "acceptable" ranges

provided in the manufacturer's recommendations, the

technician should be encouraged to align the vehicle

to the preferred settings and not just within the

range. Ask for a print-out or record of the

post-alignment settings for future reference.

-

What does UTQG mean?

To help consumers compare a passenger car tire's

tread wear rate, traction performance, and

temperature resistance, the federal government

requires tire manufacturers to grade tires in these

three areas. This grading system, known as the

Uniform Tire Quality Grading System, provides

guidelines for making relative comparisons when

purchasing new tires. Although this rating system is

very helpful when buying new tires, it is not a

safety rating or guarantee of how well a tire will

perform or how long it will last. Other factors such

as personal driving style, type of car, quality of

the roads, and tire maintenance habits have a

significant influence on your tire's performance and

longevity. Tread wear grades are an indication of a

tire's relative wear rate. The higher the tread wear

number is, the longer it should take for the tread

to wear down. For example, a tire grade of 400

should wear twice as long as a tire grade of 200.

Traction grades are an indication of a tire's

ability to stop on wet pavement. A higher graded

tire should allow you to stop your car on wet roads

in a shorter distance than a tire with a lower

grade. Traction is graded from highest to lowest as

"AA", "A", "B", and "C". Temperature grades are an

indication of a tire's resistance to heat. Sustained

high temperature (for example, driving long

distances in hot weather), can cause a tire to

deteriorate, leading to blowouts and tread

separation. From highest to lowest, a tire's

resistance to heat is graded as "A", "B", or "C".

●

How many years do collector tires last?

Experience

has shown that when properly stored and cared

for, most street tires have a useful life

in service of between six to eight years.

Even when the tires look usable, it is

recommended that all tires (including spare

tires) that were made more than eight years ago be

replaced with new tires. Environmental

conditions like exposure to sunlight and coastal

climates, as well as poor storage and infrequent

use, accelerate the aging process. In ideal

conditions, a tire may have a life expectancy

that exceeds ten years from its date of

manufacture. However, such conditions are

rare. Aging may not exhibit any external

indications and, since there is no

non-destructive test to assess the

serviceability of a tire, even an inspection

carried out by a tire expert may not reveal the

extent of any deterioration. Check with the laws

of your state to determine if a shorter period

of time is required. Several states forbid tires

in service that are over six years old from the

build date.

●

How can I tell

when my tires were made?

-

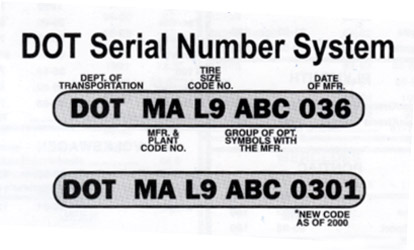

To the right are two examples of

DOT Safety Standard Codes. "DOT"

means the tires meet or exceed

the Department of

Transportation's safety

standards. "MA" is the code

number assigned by the DOT to

the manufacturing plant. "L9" is

the tire size code. "ABC: is a

group of symbols, optional with

the manufacturer to identify the

brand or other significant

characteristics of the tire. The

"0301" means the tire was made

during the 3rd week of 2001 (the

first two numbers designate the

week it was manufactured and the

last two numbers indicate the

year).

|

|

●

How much weight does

it take to balance whitewall tires? It is

not unusual to add up to 1% or more of the total

weight of the wheel and tire. Six ounces of weight

may be required to

balance a wheel and whitewall tire weighing 60

pounds, as an example. Should an extremely high amount of

weight be required, a responsible and

knowledgeable installer will dismount the tire

and rotate it 180 degrees and re-balance in an

attempt to lessen the amount of weight required.

Installers with modern equipment can also match

the high and low spots of the wheels and tires

to obtain a precision balance. Try to locate a

tire installer who has experience with whitewall

tires and understands that the whitewall tire

stripe is thick and heavy and only on one side

of the tire. It takes more weight to off-set the

weight of the whitewall stripe which some

technicians fail to realize. Furthermore, if you

are running inner-tubes, these can also add to

the need for more tire weights. Since our wheels

are "lug centric" not "hub centric", we strongly

recommend that the

technician use a finger attachment when

balancing so as to balance the wheel and tire

from the stud holes as opposed to using a cone

in the center hole which will not produce as

precision of a balancing job. Insist on

"stick-on" type weights, not clip-on style

weights. Clip-on weights will not stay put

with some brands of tires and will fall-off.

They may also ruin your chrome plating. The

tire technician must ALWAYS balance on a

static setting, never dynamic setting. For

questions, please call us for assistance.

●

I have an

inner-tube failure. What are the possible causes

and repairs?

1)

The most probable cause we have

found are inspection tags or foreign

objects/sharp edges in the tire itself.

These conditions can puncture and spoil an

inner-tube immediately or gradually over

time. We recommend that the offending tire

be carefully inspected. Inspection

tags are glued-in and measure about 1/2"

long by 1/4" wide plus or minus. They are

often difficult to remove. I have found as

many as 8 of them in one tire! They are even

located high up on the inside of the tire

sidewall. You can use a hair dryer to loosen

them or very, very carefully grind them off.

Additionally,

inspect the tire itself for any sharp edges

or "mold marks" that may protrude enough to

puncture the inner tube. We have found

foreign objects inside tires before such as

a piece of gravel or metal filing. These

objects can kill an inner-tube

2)

The second major cause of inner-tube

failure can be improper installation. Sadly,

an installer may simply not have the

knowledge or experience in dealing with

inner-tubes and the tube gets bunched up,

over-inflated or not positioned properly in

the wheel and tire. The technician may not

use baby powder to ease the installation. We

suggest finding an installer who has

experience with inner-tubes and wire wheels.

Avoid "big-box" type stores that don't have

experience, time or patience to properly

mount tires on wire wheels.

3)

Defective tubes can also occur and

despite everything going smoothly, the inner

tube simply fails and needs replacement.

An improperly sized inner tube may not match

your application. Make sure you have the

right size tube. For radial tires, use only

a radial inner-tube. Be careful that the

valve stem is not too big for the valve stem

hole in the wheel. This could cause a leak

due to chaffing as the valve stem tears

itself off on the choking effect of the

smaller valve stem hole in the wheel.

Speaking of valve stems, make certain that

the valve stem itself is in proper alignment

with the valve stem hole and not at a

cock-eyed angle.

4)

Sharp edge in the wheel causing

inner-tube failure. Despite using

the utmost care on our end, a sharp edge

could be puncturing your inner tube from

something within the wheel. This rarely ever

occurs but it cannot be ruled out if all of

the above listed conditions do not exist.

Look carefully at the inside of your wheel

for any sharp edges in the rim or protruding

through the liner material. You can run your

hand over the interior of the wheel and

sealer area and see if you can find a sharp

edge. If you do locate a "sharp", please

call or email us if it is our wheel and

under warranty for further instructions. Be

careful the edge or "sharp" does not injure

you. If you attempt to repair the problem

yourself, make certain that your actions do

not violate any warranty that may be on your

wheel that forbids self-repair. Here are the

steps we would take:

A)

Smooth off the sharp edge you discovered.

Smooth it flat as possible. A file or Emery

cloth may be sufficient. We are assuming

that the sharp edge will be very small.

B)

Clean the inside of the wheel thoroughly

using Acetone. We want the sealer area as

clean as possible. Don't pull off all the

existing sealer, just clean it.

C)

After identifying the problem area, apply GE

or Dow Corning brand 100% pure silicone.

Make certain the material you purchase says

it is "Non-corrosive". We

like to have clear silicone so you can see

if you have covered up the area involved and

that you have it thick enough but not too

thick. You can purchase this material at

Home Depot stores. You will only repair the

area involved not the entire sealer area. It

is not necessary to lay a coat of silicone

over the entire sealer area. Do not remove

the entire inner-liner of the wheel to make

a repair on a single area.

C) Lay

down a thin coat of silicone over the

involved area and smooth it flat with a

putty knife. You can apply the new silicone

material directly over the area involved. Be

careful that you do not allow the silicone

to get close to the lip or bead of the rim.

Material stacking up on the bead area may

prevent your tire from seating or beading-up

properly. If you accidentally get some

silicone in this area, clean it off as soon

as possible or wait until it drys and then

remove it.

D)

Allow the silicone to dry for 3-5 days

before mounting your tire. The silicone

takes a few days to set-up and fully dry.

With these steps taken, you should not have

any further problems. Make certain that the

coat you apply is thin and not too high or

it will interfere with how the inner-tube

will fit inside the wheel.

Regarding

Flaps or Liners. Some owners use

flaps or liners to protect against sharp

edges in the wheels harming the inner tubes.

A properly installed liner with silicone

does the job that a flap or liner would do

in nearly all cases. Flaps and liners can

introduce problems of their own if not

properly sized. They can also make the

wheel, tire and tube more difficult to

balance. If you decide to use a flap or

liner, get the right size one for the job or

get advice on how to fabricate one from an

inner-tube. For our brands of wheels that we

sell, we do not recommend tubes or flaps.

If

you have any questions, please call or email

us. We are glad to help and we want you back

up and running as soon as possible.

|

friendly advice is

a phone call or email away |

Motorspot,

Inc.

427 Industrial Way, Unit

C - Fallbrook, California

92028

Telephone:

760-731-8301 (Phone calls returned)

Monday through Friday 9 - 5 PST

email

12/29/20 |

Return to the home page

|